Super Lowest Price Industrial Rotary Dryer - Dealing with the new process of furfural waste water closed evaporation circulation – Jinta

Super Lowest Price Industrial Rotary Dryer - Dealing with the new process of furfural waste water closed evaporation circulation – Jinta Detail:

National invention patent

The characteristics and treatment method of furfural wastewater: It has strong acidity. The bottom wastewater contains 1.2%~2.5% acetic acid, which is turbid, khaki, light transmittance <60%. In addition to water and acetic acid, it also contains extremely A small amount of furfural, other trace organic acids, ketones, etc. The COD in the wastewater is about 15000~20000mg/L, BOD is about 5000mg/L, SS is about 250mg/L, and the temperature is about 100℃. If the waste water is not treated and discharged directly, the water quality will inevitably be seriously polluted and the structure of the ecological environment will be destroyed. The general treatment methods mainly include: chemical method, biological method (upstream aerobic reaction, filtered aerobic reaction, etc.), aerobic treatment process (SBR reaction, contact oxidation reaction), among which aerobic treatment is another after anaerobic treatment A treatment process, in order to ensure the standard of effluent water quality, is an indispensable treatment process in the treatment of furfural wastewater. However, in the project commissioning stage, aerobic commissioning will waste a lot of time and money, which will increase the cost of water treatment projects, such as commissioning. If it is not good, it will make the overall process unable to run, so aerobic debugging is very important to the overall project, but nutrients are essential in aerobic debugging.

Waste water produced by furfural is belong to Complex organic wastewater, which contain cetic acid, furfural and alcohols, aldehydes, ketones, esters, organic acids and many kinds of organics, PH is 2-3, high concentration in COD,and bad in biodegradability.

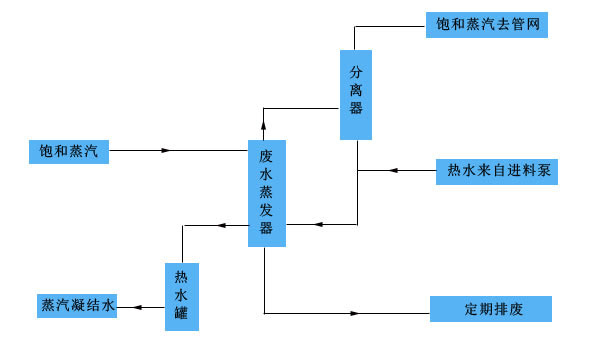

The process regard saturated steam as heat source, evaporation system make.

Waste water vaporized, boost pressure to reach production requirement, recycle the furfural and heat from the waste water to realize waste water recycle in production process. The device adopt automatic program to control.

Product detail pictures:

Related Product Guide:

Our intention should be to fulfill our consumers by offering golden provider, superior price and superior quality for Super Lowest Price Industrial Rotary Dryer - Dealing with the new process of furfural waste water closed evaporation circulation – Jinta , The product will supply to all over the world, such as: Iran, Angola, kazan, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We'll work whole-heartedly to improve our solutions and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!