PriceList for Asme Pressure Vessel Industry - Furfural and corn cob produce furfural process – Jinta

PriceList for Asme Pressure Vessel Industry - Furfural and corn cob produce furfural process – Jinta Detail:

Summary

The containing Pentosan plant fiber materials (like Corn cob, peanut shells, cotton seed hulls, rice hulls, sawdust, cotton wood) will hydrolysis into pentose in the fluence of the certain temperature and catalyst, Pentoses leave off three water molecules to form furfural

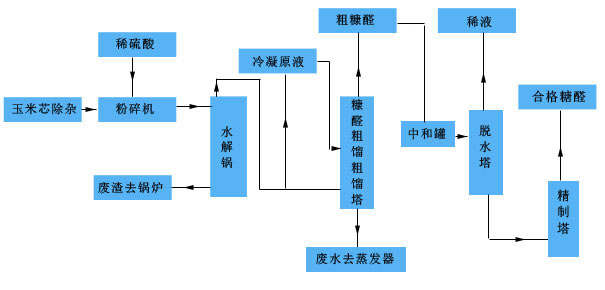

The corn cob is used by the materials usually, and after a series of process that include Purification, crushing, with acid hydrolysis, mash distillation, neutralization, dewatering, refining get the qualified furfural in the end.

The “Waste” will be sent to the boiler combustion, the ash can be used as filled material for the infrastructure or organic

Third, the process flow chart:

Chemical nature

Because furfural has aldehyde and dienyl ether functional groups, furfural has the properties of aldehydes, ethers, dienes and other compounds, especially similar to benzaldehyde. Under certain conditions, furfural can undergo the following chemical reactions:

Furfural is oxidized to produce maleic acid, maleic anhydride, furoic acid, and furanic acid.

In the gas phase, furfural is oxidized by a catalyst to generate anhydrous malic acid.

Furfural hydrogenation can produce furfuryl alcohol, tetrahydrofurfuryl alcohol, methyl furan, methyl tetrahydrofuran.

Furan can be made from furfural steam and water steam after decarburization with appropriate catalyst.

Furfural undergoes Conicaro reaction under the action of strong alkali to produce furfuryl alcohol and sodium furoate.

Furfural can undergo Boqin reaction under the action of fatty acid salt or organic base and condense with acid anhydride to form furan acrylic acid.

Furfural is condensed with phenolic compounds to produce thermoplastic resin; it is condensed with urea and melamine to make plastic; and it is condensed with acetone to make furfurone resin.

Corncob uses

1. It can be used to extract heavy metals from wastewater, and it can be used to prevent hot thin steel sheets from sticking together.

2. It can be used in the production of cardboard, cement board and cement brick, and it can be used as a filler for glue or paste.

3. It can be used as feed premix, methionine, lysine, lysine protein powder, betaine, various mold preparations, antifungal agents, vitamins, phospholipids, phytase, flavoring agents and madurin, safety Common enzyme choline chloride, etc., veterinary drug additives, nutritional carriers, can replace secondary powder, and is also one of the main raw materials for the fermentation of biological products.

4. Used for processing furfural and xylitol.

Product detail pictures:

Related Product Guide:

We emphasize advancement and introduce new products into the market each year for PriceList for Asme Pressure Vessel Industry - Furfural and corn cob produce furfural process – Jinta , The product will supply to all over the world, such as: United States, Victoria, Jamaica, Now the competition in this field is very fierce; but we will still offer best quality, reasonable price and most considerate service in an endeavor to achieve win-win goal. "Change for the better!" is our slogan, which means "A better world is before us, so let's enjoy it!" Change for the better! Are you ready?

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.