Good Wholesale Vendors Alcohol Plant - Five-Column Three-Effect Multi-Pressure Distillation Process – Jinta

Good Wholesale Vendors Alcohol Plant - Five-Column Three-Effect Multi-Pressure Distillation Process – Jinta Detail:

Overview

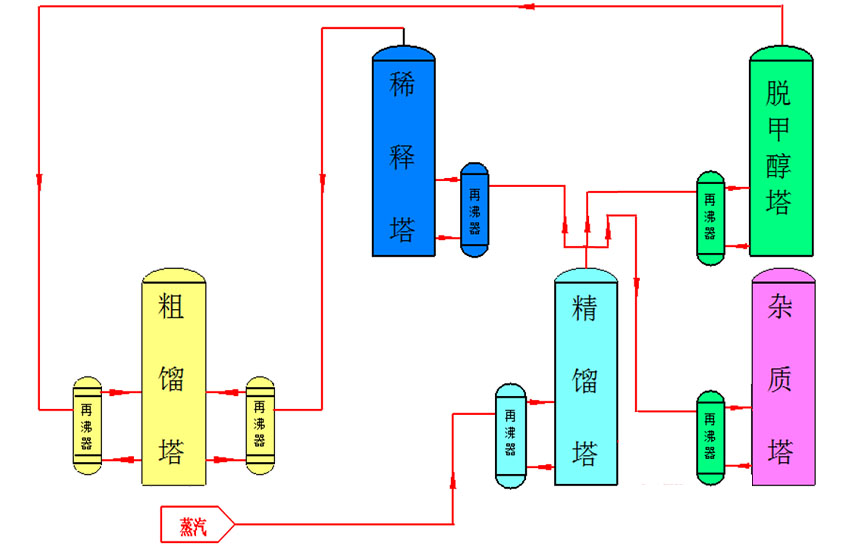

The five-tower three-effect is a new energy-saving technology introduced on the basis of the traditional five-tower differential pressure distillation, which is mainly used for the production of premium grade alcohol. The main equipment of the traditional five-tower differential pressure distillation includes a crude distillation tower, a dilution tower, a rectification tower, a methanol tower, and an impurity tower. The heating method is that the rectification tower and the dilution tower are heated by the primary steam through the reboiler, and the rectification tower wine vapor supplies heat to the crude distillation tower through the reboiler. The dilution tower wine vapor supplies heat to the methanol tower through the reboiler. The impurity tower uses direct steam to supply heat directly, and the steam consumption is large. The main equipment of the five-column three-effect differential pressure distillation is also a crude distillation tower, a dilution tower, a rectification tower, a methanol tower, and an impurity tower.

Second, the process characteristics

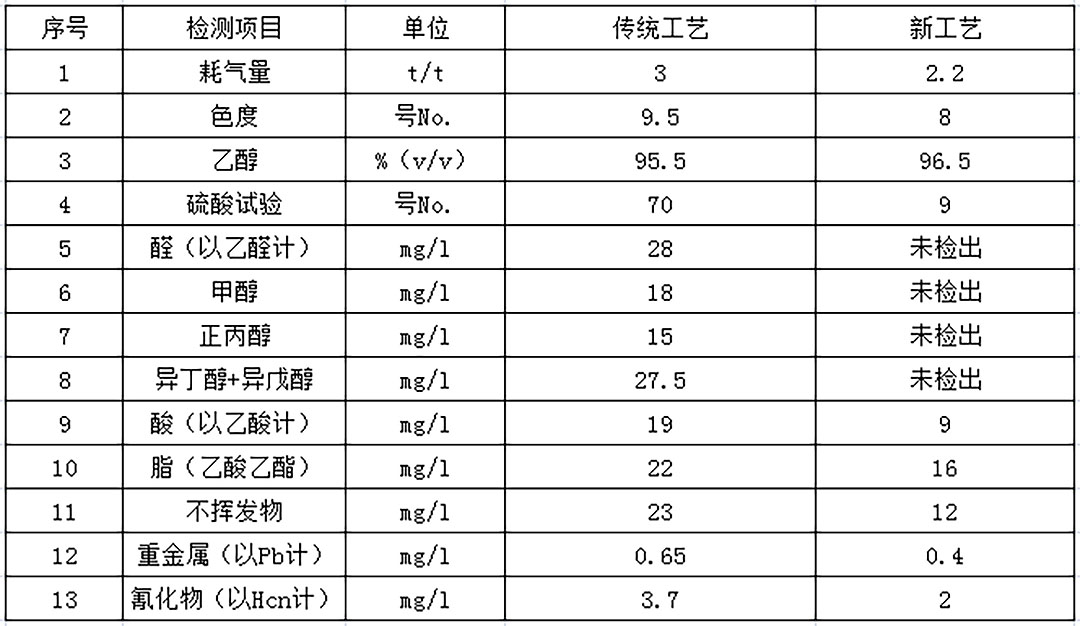

1. The three-effect thermal coupling process of heating the dilution tower, de-methanol tower, impurity tower, and then diluting tower and de-methanol tower to heat the crude distillation tower to minimize steam consumption. The production of tons of excellent grade alcohol consumption is 2.2 tons.

2. The degassing section and the separator are arranged in the upper part of the crude distillation tower to reduce impurities such as solids contained in the crude alcohol entering the rectification system, thereby improving the purity of the crude alcohol.

3. The crude distillation tower reboiler adopts the patented technology of thermosyphon circulation heating instead of the forced circulation heating mode, and the power saving effect is remarkable, and the blockage phenomenon of the reboiler heat exchange tube is eliminated.

4. The copper piper packing is added to the distillation system to improve the taste quality of the finished alcohol.

Third, heating method

The key to the energy saving of this process is its heating mode, in which the primary steam is passed through a reboiler to heat the rectification column. The distillation tower wine steam is supplied to the methanol column and the dilution tower through a methanol column reboiler and a dilution column reboiler. The dilution tower and the methanol tower wine vapor are respectively passed through the crude distillation column reboilers A and B to supply the crude distillation tower. The distillation tower wastewater flashes steam to supply the impurity tower. One tower enters the steam and five towers to achieve three-effect thermal coupling to achieve energy-saving purposes. The production of tons of excellent grade alcohol consumption is 2.2 tons.

Fourth, the material trend

The fermented mature mash is fed from the top of the crude distillation column after two stages of preheating. The wine vapor at the top of the crude distillation tower is condensed and then dilute and purified into a dilution tower to dilute the crude alcohol to 12-18% (v/v). The bottom liquor is preheated and then enters the rectification tower at the upper side line of the distillation column. The alcohol (96% (v/v)) is taken out to the de-methanol column to further remove impurities such as methanol, and the finished alcohol is taken out from the bottom.

Other advantages

1. In terms of power saving, the thermosiphon reboiler cycle heating method replaces the forced circulation heating mode, and utilizes our patented technology to avoid the blockage of the reboiler heat exchange tube. The consumption of alcohol per ton of alcohol is 20kwh. Compared with the improvement of the first five tower differential pressure distillation 40-45kwh, the power saving is 50%, which avoids the maintenance of the reboiler forced circulation pump and prolongs the service life of the reboiler.

2. Impurity wine treatment: Impurity alcohol from the crude distillation tower, dilution tower, methanol tower, etc., and light wine from the fusel oil separator enter the impurity tower, and the industrial alcohol is extracted after the impurity tower condenser is exhausted. The fusel oil is extracted, and the crude alcohol taken out from the upper side line is then passed to the dilution tower to increase the premium grade alcohol yield.

3. In terms of improving the quality of alcohol, in addition to the technological measures, the structure of the equipment has also been improved. The crude distillation tower is equipped with a crude wine purification device, and the distillation tower is provided with a copper filler sulfur removal device to ensure the purity and taste of the alcohol.

Sixth, excellent grade alcohol energy consumption and quality comparison table.

Product detail pictures:

Related Product Guide:

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Good Wholesale Vendors Alcohol Plant - Five-Column Three-Effect Multi-Pressure Distillation Process – Jinta , The product will supply to all over the world, such as: Bangladesh, Buenos Aires, Gabon, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!