Good User Reputation for Alcohol Making Equipment - Ethanol production process – Jinta

Good User Reputation for Alcohol Making Equipment - Ethanol production process – Jinta Detail:

First, raw materials

In the industry, ethanol is generally produced by a starch fermentation process or an ethylene direct hydration process. Fermentation ethanol was developed on the basis of winemaking and was the only industrial method for producing ethanol for a long period of time. The raw materials of the fermentation method mainly include cereal raw materials (wheat, corn, sorghum, rice, millet, oats, etc.), potato raw materials (cassava, sweet potato, potato, etc.), and sugar raw materials (beet, sugar cane, waste molasses, sisal, etc.) And cellulose raw materials (wood chips, straw, etc.).

Second, the process

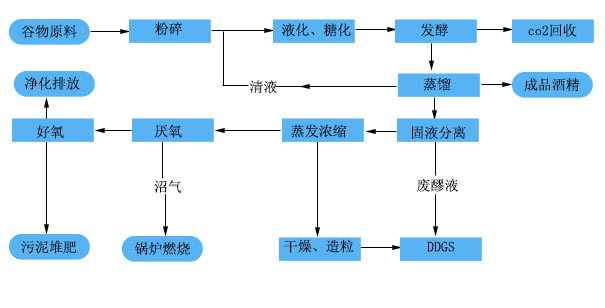

Cereal raw material

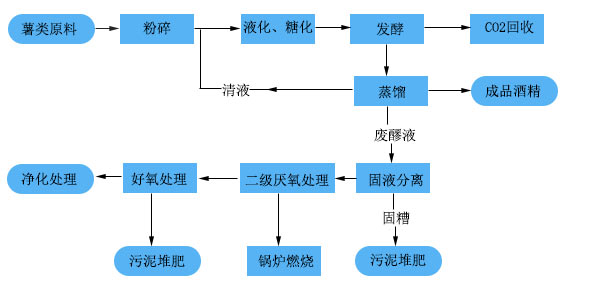

Potato raw materials

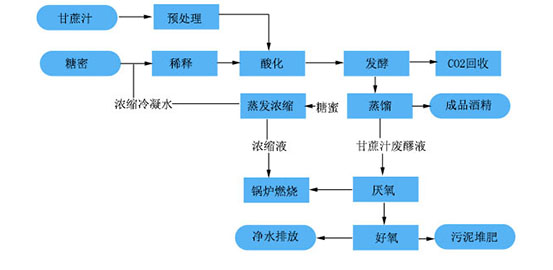

Glycogen raw materials

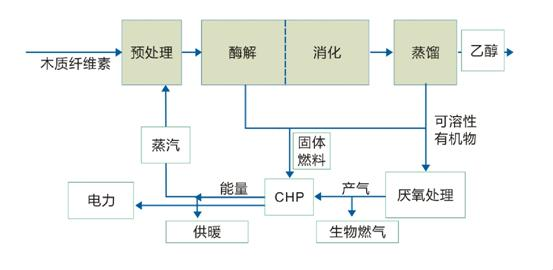

Cellulose raw materials

Synthesis method

The direct hydration of ethylene is the direct reaction of ethylene with water in the presence of heat, pressure and in the presence of a catalyst to produce ethanol:

CH2═CH2 + H-OH→C2H5OH (The reaction is carried out in two steps. The first step is to form an organic mercury compound in a water-tetrahydrofuran solution with a mercury salt such as mercury acetate, and then reduce it with sodium borohydride.) – Ethylene can be taken from petroleum cracking gas in large quantities, with low cost and large output, which can save a lot of food, so it develops very quickly.

It can also be converted into syngas by coal chemical industry, directly synthesized or made by industrial hydrogenation of acetic acid.

Third, the quality standard

According to the customers needs, the ethanol production unit can reach the relevant standards (GB10343-2008 special grade, superior grade, general grade, GB18350-2013, GB678-2008) or other international standards.

Fourth, the remarks

The company can undertake a complete turnkey project such as alcohol, chemical, pharmaceutical, DDGS.

The “Golden Character” brand distillation and ancillary equipment have a domestic market share of over 40%. In 2010-2013, the company ranked first in the same industry for four consecutive years.

Product detail pictures:

Related Product Guide:

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for Good User Reputation for Alcohol Making Equipment - Ethanol production process – Jinta , The product will supply to all over the world, such as: United Arab emirates, Sevilla, Munich, There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.