factory Outlets for Alcohol Brewing Machine - Waste water containing salt evaporation crystallization process – Jinta

factory Outlets for Alcohol Brewing Machine - Waste water containing salt evaporation crystallization process – Jinta Detail:

Overview

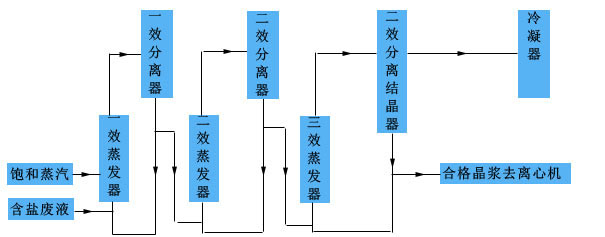

For the characteristics of “high salt content” of waste liquid produced in cellulose, salt chemical industry and coal chemical industry, the three-effect forced circulation evaporation system is used to concentrate and crystallize, and the supersaturated crystal slurry is sent to the separator to obtain crystal salt. After separation, the mother liquor returns to the system to continue. Circulating concentration.

The device is controlled by automatic program. Evaporation tons of wastewater consumes 0.3 to 0.35 tons of steam.

Second, the process flow chart:

Waste steam evaporation device using secondary steam treatment of dryer

1. Utility model patent number

Second, an overview

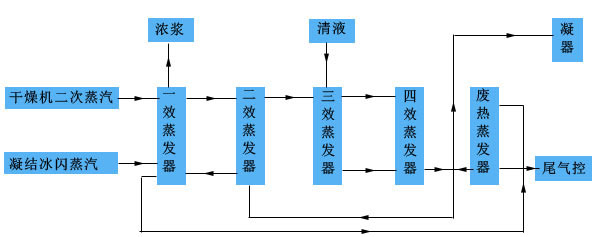

Adopting “four-effect, falling film, and pressure-reducing” evaporation system, the falling film evaporator adopts the patent technology of “three-level film”, using the secondary steam of steam dryer and steam condensed water as the heat source, and setting the waste heat evaporator to dry again. Machine waste steam, the waste clear liquid is concentrated and evaporated, the thick slurry is sent to the dryer, and the condensed water is evaporated to the water treatment plant.

The device is controlled by automatic program. The evaporation system does not need to replenish steam once.

Third, the process flow chart:

DDGS complete set

First, the patent number

National invention patent

Second, an overview

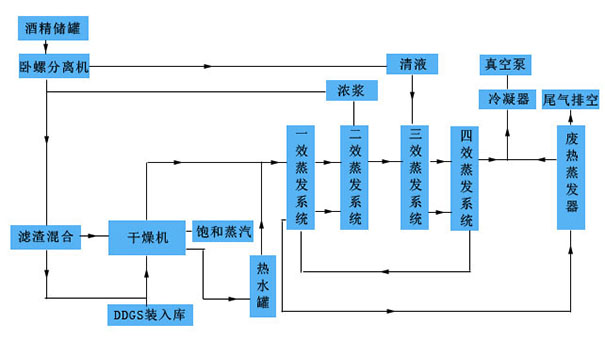

The distillers grains are produced by a full drying process, that is, dried distillers grains containing soluble solids are called DDGS (Distillers Dried Grains with Solubles).

The device uses mechanical separation, steam drying, waste heat evaporation and weighing and packaging four units to turn waste materials that are seriously polluting the environment into treasures, and obtain high-protein feeds that are easy to store, easy to transport, and nutritious. It solves the environmental problems that restrict the development of enterprises, and at the same time brings considerable economic benefits. The device is controlled by automatic program.

Third, the process flow chart

Product detail pictures:

Related Product Guide:

We're proud from the higher client fulfillment and wide acceptance due to our persistent pursuit of high quality both on product and service for factory Outlets for Alcohol Brewing Machine - Waste water containing salt evaporation crystallization process – Jinta , The product will supply to all over the world, such as: Brasilia, Saudi Arabia, Korea, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.