factory Outlets for Alcohol Brewing Machine - Threonine continuously crystallization process – Jinta

factory Outlets for Alcohol Brewing Machine - Threonine continuously crystallization process – Jinta Detail:

Threonine introduction

L-threonine is an essential amino acid, and threonine is mainly used in medicine, chemical reagents, food fortifiers, feed additives, etc. In particular, the amount of feed additives is increasing rapidly. It is often added to the feed of juvenile piglets and poultry. It is the second restricted amino acid in pig feed and the third restricted amino acid in poultry feed. Adding L-threonine to compound feed has the following characteristics:

① It can adjust the amino acid balance of feed and promote the growth of poultry and livestock;

② It can improve meat quality;

③ It can improve the nutritional value of feed with low amino acid digestibility;

④ It can reduce The cost of feed ingredients; therefore, it has been widely used in the feed industry in EU countries (mainly Germany, Belgium, Denmark, etc.) and American countries.

The production and detection method of L-threonine

The production methods of threonine mainly include fermentation method, protein hydrolysis method and chemical synthesis method. Microbial fermentation method produces threonine, which has become the current mainstream method due to its simple process and low cost. There are many methods for determining threonine content in the middle of fermentation, mainly including amino acid analyzer method, ninhydrin method, paper chromatography method, formaldehyde titration method, etc.

Paten No.ZL 2012 2 0135462.0

Summary

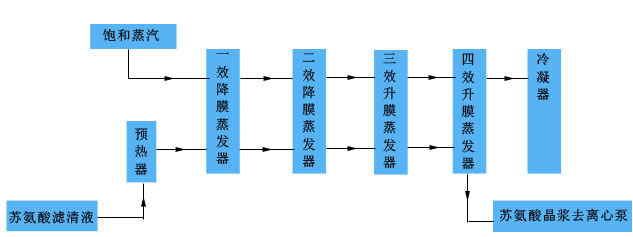

Threonine filter clogging liquid will generate crystal in the condition of low concentration evaporation, In order to avoid crystal precipitation, the process will adopt the mode of four-effect evaporation to realized clear and closed production. Crystallization is the Self-developed Oslo elutriation crystallizer without stirring

The device adopt automatic program to control.

Third, the process flow chart:

Product detail pictures:

Related Product Guide:

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for factory Outlets for Alcohol Brewing Machine - Threonine continuously crystallization process – Jinta , The product will supply to all over the world, such as: Lesotho, Jakarta, Cairo, Each customer's satisfactory is our goal. We are looking for long-term cooperation with each customer. To meet this, we keep up our quality and provide extraordinary customer service. Welcome to our company, we are expecting to cooperate with you.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!